When I get a little money I buy books; and if any is left, I buy food and clothes. – Desiderius Erasmus

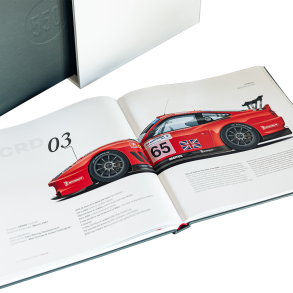

Vintage Motorsport Books

The vintage books displayed below are for the most part used and no longer in print. These are the same books that form the basis of the Grand Prix History Library and the links provided should assist you in obtaining similar copies. As with any used book purchase please read all descriptions carefully and “good luck hunting!”.

Two Summers offers a fresh, revealing and highly personal window into the culture of Grand Prix racing as it was during the 1954 and 1955 championships. The core of this book is devoted to individual portraits of the twelve races that comprised the 1954-55 seasons in which the W 196 R participated. Of those races, Fangio won seven and Moss won two. Two Summers offers a fresh, revealing and highly personal window into the culture of Grand Prix racing as it was during the 1954 and 1955 championships. The core of this book is devoted to individual portraits of the twelve races that comprised the 1954-55 seasons in which the W 196 R participated. Of those races, Fangio won seven and Moss won two.With its carefully-crafted observations and conclusions, given added drama by its richly-detailed illustrations, there are numerous examples of the energy and dynamic nature of these racing seasons â?? not the least being abundant evidence that Fangio was indeed the ultimate master of the art and science of racing a Grand Prix automobile, and that the W 196 R was the instrument with which he honed his skills. This book captures the decisive moments when victory – hanging in the balance – was tilted towards Fangio by his own steady hand on the wheel and iron discipline. The W 196 R’s racing days may be long gone, but it remains a shining star of Mercedes-Benz’ participation in motor sport heritage events worldwide. It’s this timeless appeal of the W196R that gives this book its vitality, charm and enduring attraction. |

||||||

Buy from Amazon by Brian Redman, Jim Mullen |

Buy from Amazon and a Year of Living Dangerously by John Julian |

Buy from Amazon by Carlos Eduardo Jalife-Villalon |

||||

|

||||||

Buy from AlibrisThe 1903 Irish Gordon Bennett by Bob Montgomery |

Buy from AlibrisThe Gordon Bennett Races by Lord Montagu |

Buy from Alibris of Grand Prix Driving by Niki Lauda |

Buy from AlibrisAyrton Senna’s Principles of Race Driving by Ayrton Senna |

Buy from AlibrisCompetition Driving by Alain Prost |

Buy from AlibrisSpeed was my Life by Alfred Neubauer |

|

A completely revised version of one of the best-selling motorcycle riding skills books of all time. Today’s super high-performance bikes are the most potent vehicles ever sold to the public and they demand advanced riding skills. Get it right, and a modern motorcycle will provide you with the thrill of a lifetime; get it wrong and you’ll be carted off in a meat wagon. The line between ecstasy and agony is so thin that there is absolutely no margin for error. Total Control provides you with the information you need to stay on the healthy side of that line, providing a training course developed and perfected through decades of professional training in Lee Parks’ Total Control Advanced Riding Clinic. This is the perfect book for riders who want to take their street riding skills to a higher level. Total Control explains the ins and outs of high-performance street riding. Lee Parks, one of the most accomplished riders, racers, authors and instructors in the world, helps riders master the awe-inspiring performance potential of modern motorcycles. This book gives riders everything they need to develop the techniques and survival skills necessary to become a proficient, accomplished, and safer street rider. High quality photos, detailed instructions, and professional diagrams highlight the intricacies and proper techniques of street riding and the knowledge gained will apply to all brands of bikes from Harley-Davidson and Suzuki to Ducati and Kawaski to Honda and BMW and more! Readers will come away with a better understanding of everything from braking and cornering to proper throttle control, resulting in a more exhilarating yet safer ride. A completely revised version of one of the best-selling motorcycle riding skills books of all time. Today’s super high-performance bikes are the most potent vehicles ever sold to the public and they demand advanced riding skills. Get it right, and a modern motorcycle will provide you with the thrill of a lifetime; get it wrong and you’ll be carted off in a meat wagon. The line between ecstasy and agony is so thin that there is absolutely no margin for error. Total Control provides you with the information you need to stay on the healthy side of that line, providing a training course developed and perfected through decades of professional training in Lee Parks’ Total Control Advanced Riding Clinic. This is the perfect book for riders who want to take their street riding skills to a higher level. Total Control explains the ins and outs of high-performance street riding. Lee Parks, one of the most accomplished riders, racers, authors and instructors in the world, helps riders master the awe-inspiring performance potential of modern motorcycles. This book gives riders everything they need to develop the techniques and survival skills necessary to become a proficient, accomplished, and safer street rider. High quality photos, detailed instructions, and professional diagrams highlight the intricacies and proper techniques of street riding and the knowledge gained will apply to all brands of bikes from Harley-Davidson and Suzuki to Ducati and Kawaski to Honda and BMW and more! Readers will come away with a better understanding of everything from braking and cornering to proper throttle control, resulting in a more exhilarating yet safer ride. |

||||||

Buy from Amazon Technical Analysis 2011/2012 by Giorgio Piola |

Buy from Amazon Technical Analysis 2010/2011 by Giorgio Piola |

Buy from AmazonFormula 1: Technical Analysis 2009/2010 by Giorgio Piola |

Buy from Amazon Technical Analysis 2008/2009 by Giorgio Piola |

Buy from Amazon Technical Analysis 2007/2008 by Giorgio Piola |

Buy from AmazonThe Racing Driver by Denis Jenkinson |

|

Buy from Amazon Professional Race Driving Techniques by Ross Bentley |

Buy from AmazonSpeed Secrets 2: More Professional Race Driving Techniques by Ross Bentley |

Buy from AmazonInner Speed Secrets: Mental Strategies by Ross Bentley |

Buy from Amazon Engineering the Driver by Ross Bentley |

Buy from Amazon The Complete Driver by Ross Bentley |

Buy from AmazonThe Technique of Motor Racing by Piero Taruffi |

|

Buy from Amazon Denis Jenkinson As an anecdote to the cookie cutter books that seem to come out the day after a driver turns his first wheel in a Grand Prix car. I purchased “My Two Lives” by René Dreyfus. During the 20’s and 30’s he drove Maseratis, Ferraris and especially Bugattis on the Grand Prix circuits of the world. In 1938 he won his greatest victory in a Delahaye at Pau where he beat the best that Mercedes had to offer. When World War II started he joined the French Army but while on leave to compete in the Indianapolis 500 he found himself stranded when Paris was overrun. Without visible means of support he opened a French restaurant and began his second career. Upon the United States entering the war, Dreyfus joined the American Army. In 1980 he returned to Europe to celebrate the 50th anniversary of his victory in the Grand Prix of Monaco. The story begins in 1914 when René was nine years old. The middle of three children he speaks of his early life with fondness, growing up in Nice. He later joined the Moto Club de Nice, which was sort of a junior league Automobile Club de Nice. Forging his mother’s signature René entered his first race and won, due to him being the only car in his class. During this time he and his brother Maurice owned a paper company with René the salesman. He somehow convinced his mother that if he had a Bugatti he would be able to get around faster and see more customers. His mother was duped and soon the boys had their first race car. In the coming years René finds himself at the center of the greatest period in the history of Grand Prix racing. His contemporaries included Chiron, Caracciola, Varzi and Nuvolari. It his observations of this period that makes this book special. As a French patriot driving against the German cars we learn how it felt for himself and his friend Louis Chiron.

The following are some quotes from his book. … Meantime, there was a new presence on the Grand Prix scene. At the Swiss GP at Bern on August 26th, I took a good long look at the Auto Union and Mercedes for the first time. There were swastikas all around, but all of us were looking at the cars. They were most unusual and enormously powerful. Four hundred fifty horsepower already, with the promise for much more. There were as many engineers in the pits as drivers. It was a gargantuan operation. The political significance of all this eluded us. All we realized was that Germany’s new chancellor was an automobile enthusiast and wanted the country’s cars to be supreme, the most powerful, the fastest, the most everything. René Dreyfus – 1934 The “racing enthusiast” was of course Adolf Hitler. …Stuck’s Auto Union was leading, but Tazio was giving him fits, until suddenly Nuvolari lost a piston just past the grandstand. He got out of his car and started walking slowly back to the pits. I was now in second place. My car was performing beautifully. Stuck’s brakes, I could sense were fading. This was Italy, and this was Tazio – and the crowd, seeing him walking, started a vigorous chant: “Nuvolari in macchina, Nuvolari in macchina!” When I pulled into the pits to refuel, Enzo and Gobbato asked me if I’d mind giving my car to Nuvolari. Of course, I wouldn’t; Tazio was the team captain. Tazio beamed, and said grazie, and I shouted a few things about how the car was behaving and he took off. He drove like only Nuvolari could, and was challenging Stuck fantastically, but he was also wearing down the Alfa’s brakes, had to pit to have them adjusted, and finished second.

René Dreyfus at Monza – 1935 For Nuvolari to play it cool and wait for something to happen to the car of Hans Stuck would be like a cat barking! It would not have been Nuvolari who only knows how to drive – flat out. While in the American Army Dreyfus had many humorous encounters especially when it related to the English language. While attending an interrogation class he was called upon to name the various battalions in a regiment. …I stood up, and rattled off the list in my best English – and when I finished, the teaching lieutenant said, fine, you missed just one. I remembered it immediately, and remembered how my English teacher in Spartenburg had told me to always aspirate an “h” sound, difficult for a Frenchman, and so I aspirated with a vengeance and :assault” came out “asshole” battalion. The room fell apart in laughter.” The lieutenant was very kind, and when everyone had quieted down, told me that I was right but my pronunciation was wrong. He wrote the word “assault” on the blackboard, and I pronounced it once more, exactly the same way I had the first time. The room broke up again. Finally, the lieutenant said that actually, on reflection, I was probably right. And we got on to other things.” Dreyfus, René and Beverly Rae Kimes. “My Two Lives”. Aztex Corporation, 1995, 1983 pp., ISBN 0-89404-080-4. |

||||||

Buy from Alibris by Chris Nixon |

Buy from AlibrisAlf Francis Racing Mechanic 1948-58 as told to Peter Lewis |

Buy from AlibrisA Racing Motorist by S.C.H. Davis |

Buy from AlibrisBits and Pieces by Prince Birabongse |

Buy from AlibrisBRM by Raymond Mays and Peter Roberts |

Buy from AlibrisThe Cruel Sport by Robert Daley |

|

Buy from AlibrisDick Seaman A racing Champion by H.R.H. Prince Chula Chakrabongse |

Buy from AlibrisGentlemen, Start Your Engines by Wilbur Shaw |

Buy from AlibrisGrand Prix by Barre Lyndon |

Buy from AlibrisGrand Prix Driver by Hermann Lang |

Buy from AlibrisWorks Driver by Piero Taruffi |

Buy from AlibrisThe Star and The Laurel by Beverly Rae Kimes |

|

Buy from Amazon by Matt Stone

|

Buy from Amazon The Cars and Bikes of a Hollywood Icon by Matt Stone |

Buy from Amazon by Matt Stone |

||||

Buy from AmazonRaymond Mays’ Magnificent Obsession by Bryan Apps |

Buy from Amazon The Official Biography of Keith Duckworth OBE by Norman Burr |

|||||

|

||||||

| For 1961, though, the uncrowned champion was handicapped in four ways. Stirling was driving last year’s car, a car with considerably less power and one entered by a private team. He had no team mates to help him but was on his own – a David against several Goliaths. The scrapbook includes over 500 illustrations | ||||||

Buy from AlibrisStirling Moss Scrapbook 1956-1960 by Stirling Moss |

Buy from AlibrisStirling Moss Scrapbook 1955 by Stirling Moss |

Buy from AlibrisStirling Moss Scrapbook 1929-1954 by Stirling Moss |

||||

Buy from Alibris by Stirling Moss |

Buy from Alibris Swiss Racing Legend by Ed Heuvink |

Buy from Alibris by Jesse Alexande |

Buy from AlibrisThe Fast Ones by Peter Miller |

Buy from AlibrisThe Encyclopedia of Motor Sport by GN Georgano |

Buy from AlibrisMotor Racing Through the Fifties by Peter Lewis |

|

Buy from AlibrisGrands Prix 1934-1939 by Rodney Walkerley |

Buy from AlibrisSir Henry Segrave by Cyril Posthumus |

Buy from AlibrisRed Arrows: Ferraris At The Mille Miglia by Giannino Marzotto |

Buy from AlibrisStirling Moss by Robert Edwards |

Buy from AlibrisThe Complete History of Grand Prix Motor Racing by Adriano Cimarosti |

Buy from AlibrisGrand Prix Racing Facts & Figures by George Monkhouse |

|

|

||||||

Buy from AlibrisPower and Glory Vol 1 by William Court |

Buy from AlibrisPower and Glory Vol 2 by William Court |

Buy from AlibrisMercedes-Benz W196 by Michael Riedner |

Buy from AlibrisThe Race Bugatti Missed by Michael Ulrich |

Buy from AlibrisPiloti, Che Gente by Enzo Ferrari |

Buy from AlibrisRacing the Silver Arrows by Chris Nixon |

|

Buy from AmazonFull Throttle by Tim Birkin |

Buy from AmazonHistory of the Grand Prix Car 1945-65 by Doug Nye |

Buy from AmazonHistory of the Grand Prix Car 1966-91 by Doug Nye |

Buy from AlibrisRed-Hot Rivals: Ferrari vs. Maserati by Karl Ludvigsen |

Buy from AlibrisThe Constant Search by Charles Mortimer |

Buy from AlibrisChallenge me the Race by Mike Hawthorn |

|

Buy from AlibrisTouch Wood by Duncan Hamilton |

Buy from AlibrisAuto Union V16 A Technical Appraisal by Ian Bamsey |

Buy from AlibrisMaserati 250F: A Technical Appraisal by Andy Hall |

Buy from AlibrisVanwall 2.5 Litre F1: A Technical Appraisal by Ian Bamsey |

Buy from AlibrisLotus 25 Coventry Clima: A Technical Appraisal by Ian Bamsey |

Buy from AlibrisCooper Cars by Doug Nye |

|

Buy from AlibrisThe Grand Prix Car 1954 to 1966 by L. J. K. Setright |

Buy from AlibrisBRM Volume 1 by Doug Nye |

Buy from AlibrisBRM Volume 2 by Doug Nye |

Buy from AlibrisBRM Volume 3 by Doug Nye |

Buy from AlibrisBRM: A Mechanic’s Tale by Dick Salmon |

Buy from AlibrisWhen the Flag Drops by Jack Brabham |

|

This small (152 pages, 12 chapters) book is comprised of a series of race chronicles spanning the years 1953-1959. It covers in the words of the author … A decade in the history of motor racing Juan-Manuel Fangio, known affectionately as “bandy legs”, won the World Championships five times, and when British drivers like Mike Hawthorn, Stirling Moss, Peter Collins and Tony Brooks emerged to challenge the Italians and Argentineans who had dominated the Grand Prix scene since the end of World War 2. While the book pays special attention to the leading British drivers he treats drivers from other nations with the respect that they deserve. In fact an important facet of the first decade after the Second World War was England’s emergence in the sport that spearheaded the efforts of the nations of the British Commonwealth that would dominate racing in the 60’s and 70’s. Chapter 7 of the book entitled “Sensation at Syracuse” tells of Tony Brooks’ win in 1955 driving a British designed and built Connaught, the first victory of its kind. The writing gives the reader the sense of being there and partaking in the astonishment of this most improbable win. The first practice session on Friday was well under way, yet the transporter carrying the Connaught teams cars was nowhere to be seen. This forced the British teammates, Brooks and Les Leston to reconnoiter the circuit on borrowed Vespa motor scooters which was not exactly conducive to finding the correct racing line or late breaking points! A more inauspicious beginning

Other chapters include the disaster at Le Mans in 1955, Moss’ great victory in the Mille Miglia, Fangio’s victory at Nurburgring over Hawthorn and Collins and what was known as the “Race of the Century” at Rheims. Each race is a legend in its own right and all are described in an excellent reporting style as if gleamed from the very best newspapers of the day which in fact they were by a writer who witnessed each one in person. As you can probably guess this is one of my favorite books which unfortunately is out of print. It should be found in one of the specialized motoring book stores in England such as Chater’s Motoring Booksellers. Lewis, Peter. “Motor Racing Through the Fifties”. Navel & Military Press, 1992, 152pp., ISBN 1-897632-15-0 |

||||||

Buy from AmazonAlfa Romeo la Monaposto Tipo A del 1931 by Luigi Fus |

Buy from AlibrisDesign and Behaviour of The Racing Car by Stirling Moss and Laurence Pomeroy |

Buy from AlibrisGrand Prix Tripoli 1925-1940 by Valerio Moretti |

Buy from AlibrisMotor Racing Circuits of Europe by Klemantaski & Frostick |

Buy from AlibrisGreat Auto Races by Richard Hough |

Buy from AlibrisA Racing Car Driver’s World by Rudolf Caracciola |

|

Buy from AlibrisCliff Allison by Graham Gauld |

Buy from Alibris 1894-1914 by Henry Serrano Villard |

Buy from Alibris by Giulio Schmidt |

Buy from Alibris by Norman Smith |

Buy from Alibris |

Buy from Alibris by Giovanni Lurani |

|

Buy from Alibris by Olivier Merlin |

Buy from Alibris by Alan Henry |

Buy from Alibris My Fifty Years of High Performance by Tony Rudd |

Buy from Alibris by Fredrik Petersens |

Buy from AlibrisHow to Watch Motor Racing by Stirling Moss |

Buy from Alibris by Robert Edwards |

|

Buy from Amazon |

Buy from Amazon by Mick Walker |

Buy from Amazon by Roy Smith |

||||

Buy from Amazon The 1961 Formula 1 season came up with a completely new rule type. The racing teams had to switch their engines from 2.5 to 1.5 liters. Ferrari found itself in a very good position. They had developed a V6 mid-mounted engine with a 120 degrees cylinder angle and a maximum output of 190 hp. The new 156 F1 had a very unusual front design. So pretty soon, many people gave it the nickname Sharknose. Technically and ostensibly, the 156F1 was the most successful development in 1961. The season ended for the Scuderia with a large success but also with a disastrous tragedy. Phil Hill became the first American Formula 1 World Champion. The German Ferrari star Wolfgang Graf Berghe von Trips, that led the ranking for most of the season, became involved in a deadly accident in Monza. Never before joy and teariness was that close on just one day. Our three different models represent all different successful GP appearances of the 156 F1 during the 1961 season. As a matter of course, all three models will reflect the special features of the respective race. Annotation: It is factual that no original Ferrari 156 F1 exists in the whole world. But after months of meticulous research and contacting countless Ferrari experts, CMC was able to get all necessary data for a harmonious model development. Thanks to that kind of knowledge about the car and its famous drivers, we are in a position to accomplish this mission impossible with true-to-the-original details and the well known CMC craftsmanship and quality. |

||||||

|

During that period he also painted pictures of famous automobile races — having been an avid fan of the sport since childhood. In 1944 he did a series of paintings for Esquire magazine in which he recreated the excitement of automobile races from the first decades of the 20th century. |

||||||

|

To his great satisfaction, these pictures proved very popular, and in the following decades he developed a large market for paintings of old cars. |

||||||

Buy from Alibris by Maurice Hamilton |

Buy from AlibrisAlfa Romeo by David Owen |

Buy from Alibris by Maurice Rowe |

Buy from AlibrisVilleneuve – A Racing Legend by Allan de la Plante |

Buy from AlibrisThe German Grand Prix by Cyril Posthumus |

Buy from AlibrisMarch: The Rise and Fall of a Motor Racing Legend by Mike Lawrence |

|

Buy from AlibrisThe Checkered Flag by Peter Helck |

Buy from AlibrisGrand Prix Carpetbagger by John Cooper with John Bentley |

Buy from AlibrisThe Checquered Flag by Douglas Rutherford |

Buy from AlibrisMemoirs of a Bugatti Hunter by Antoine Raffaelli |

Buy from AlibrisMy Cars, My Career by Stirling Moss |

Buy from AlibrisConte Maggi’s Mille Miglia |

|

|

||||||

Buy from Alibris by Valerio Moretti |

Buy from AlibrisRivals: Lancia D50 & Mercedes W196 by Cris Nixon |

Buy from AlibrisThe Incredible Blitzen Benz by Karl Ludvigsen |

||||

|

||||||

| He and his friends Dick Seaman and Laurence Pomeroy Jnr saw how it was done by Mercedes and they looked for a similar attitude from the British teams. At that time there was indeed a great gulf between the predominantly amateur albeit well-heeled British teams and the professional, government-backed German racing. | ||||||

Buy from Amazon The racing world had been awaiting the new “mini“ Silver Arrows, Mercedes-Benz W165 with great suspense. Its debut was scheduled for the GP of Tripolis, at the race track of Mellaha, on the 7th of May in 1939. Mercedes-Benz had managed to develop and build this new race car within 6 months. That was all the time they had to adapt it to the new rules that allowed only 1.5 liter engines. Hermann Lang with starting number 16 and Rudolf Caracciola with starting number 24, were the pilots of choice and they achieved a sensational double victory. Herman Lang became the victor with starting number 16 (CMC released that model already in a limited edition). Rudolf Caracciola with starting number 24 became second. With the Caracciola model, starting number 24, CMC completes its presentation of the victorious W165 twins of Tripolis that achieved an outstanding triumph for Mercedes-Benz. This zinc alloy model is hand-assembled from more than 400 parts. Each of the 30 individual stainless steel spokes is mounted by the hand. M-074 is a limited-edition of 5,000 pieces. |

||||||

Buy from Amazon |

Buy from Amazon |

Buy from Amazon |

Buy from Amazon |

Buy from Amazon |

Buy from Amazon |

|

His second life as a restaurateur is also covered in detail both during and after the war. While this might not be of direct interest to my motorsport readers it actually covers a longer period of his life. We learn of the reunion with his brother and sister and of course his famous restaurant – Le Chanteclair which over its 25-year history was the gathering place for motosport iluminaries from around the world. In closing there is a touching chapter of René and Maurice returning to Europe and the celebration of René’s victory at Manaco 50 years previous.

His second life as a restaurateur is also covered in detail both during and after the war. While this might not be of direct interest to my motorsport readers it actually covers a longer period of his life. We learn of the reunion with his brother and sister and of course his famous restaurant – Le Chanteclair which over its 25-year history was the gathering place for motosport iluminaries from around the world. In closing there is a touching chapter of René and Maurice returning to Europe and the celebration of René’s victory at Manaco 50 years previous. To show you the man Tazio was, I was entitled to my percentage of the prize money only on the laps I had run, Tazio was to get his percentage on the laps he had accomplished with my car – but he refused any money at all. He told the Scuderia people that I should receive the entire prize because had I remained in the car I might have won the race. He recognized, he told me afterwards, that instead of trying frantically to catch up, he might better have played it cooler and waited to see if the other man would falter.

To show you the man Tazio was, I was entitled to my percentage of the prize money only on the laps I had run, Tazio was to get his percentage on the laps he had accomplished with my car – but he refused any money at all. He told the Scuderia people that I should receive the entire prize because had I remained in the car I might have won the race. He recognized, he told me afterwards, that instead of trying frantically to catch up, he might better have played it cooler and waited to see if the other man would falter.